Wayland Additive

Metal parts, fast & easy

Wayland Additive exists to make electron beam additive manufacturing more effective and accessible to industry for a broader range of applications.

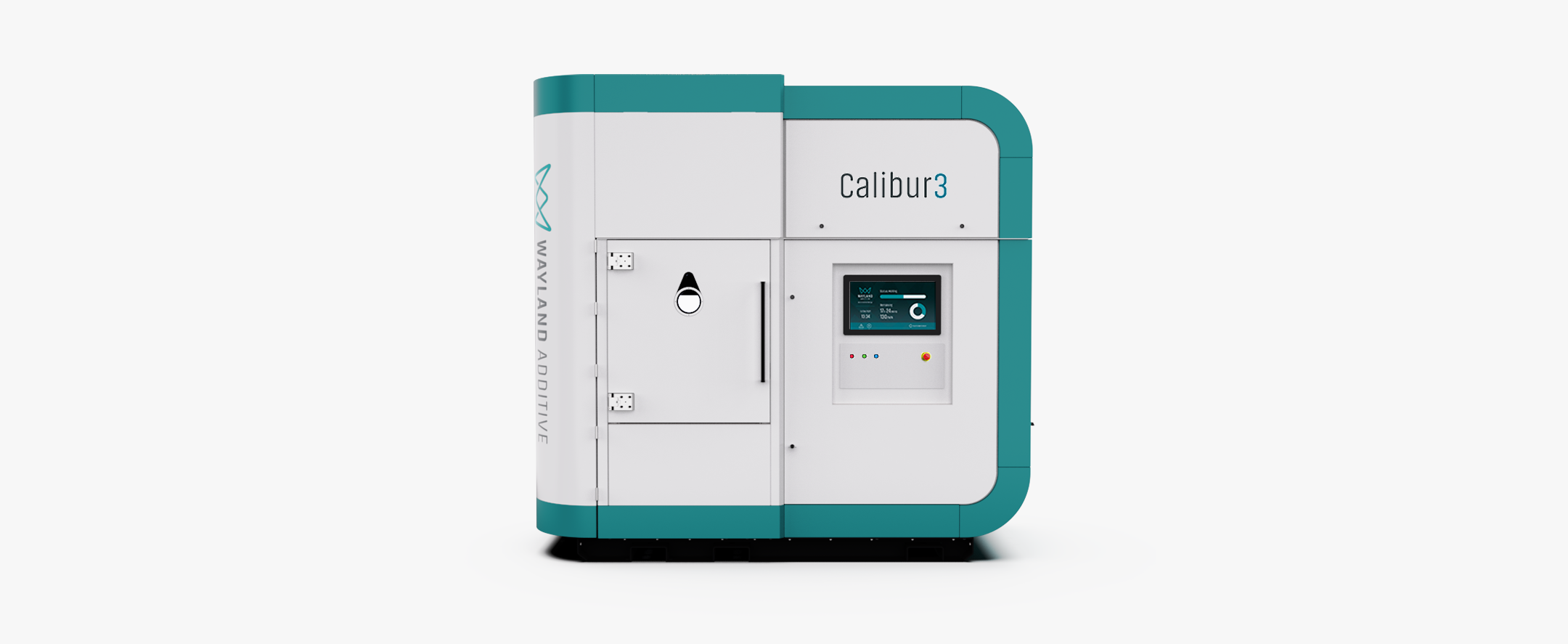

Wayland Additives Calibur3 machine contains electron-beam based technology that produces temperatues that are hot enough to melt metal powder, therefore it was clear from the outset that safety was the primary consideration for the enclosure whilst balancing the design aesthetics, ease of maintenance and user interaction of the machine on a daily basis.

The brief for Papa Bravo was to design a totally bespoke enclosure to optimise the performance of the innovative AM manufacturing equipment housed inside.

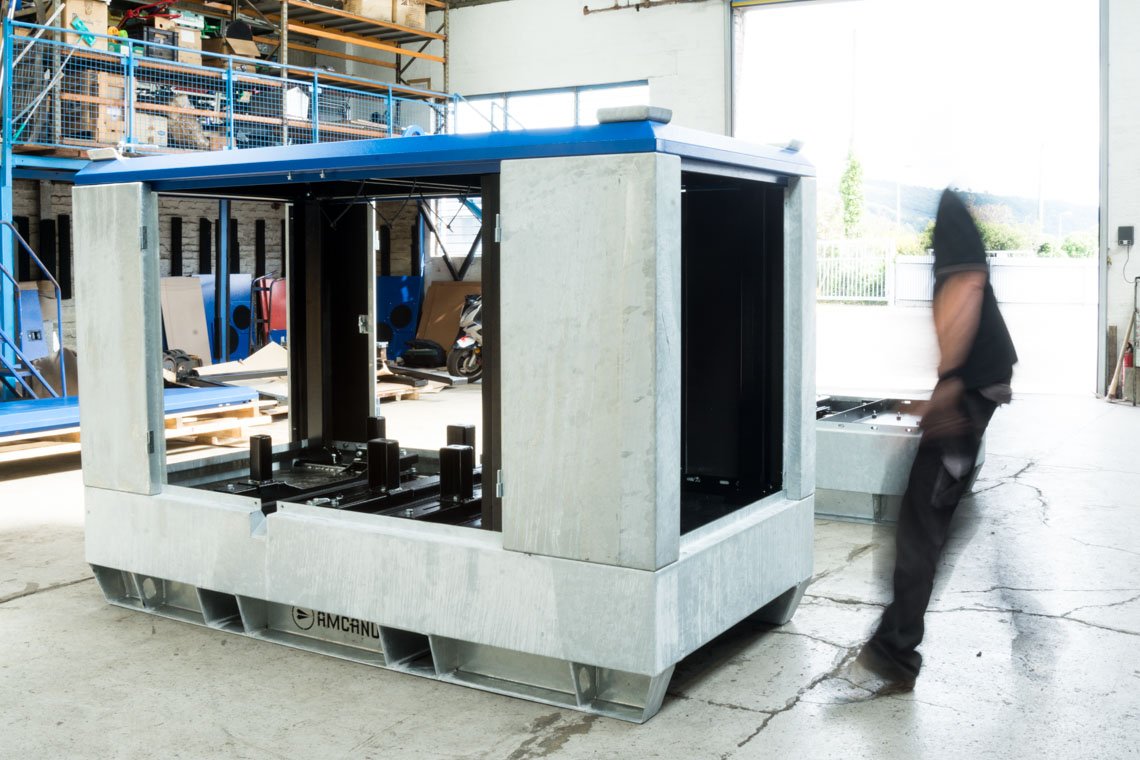

The modular design enables gradual assembly to give Wayland greater build flexibility – sections can be sub-assembled to fit specific end-user build programmes.

The enclosure is designed with lift-off doors and hatches to enable easy access to all major components. Each part is easy to remove and replace if damaged, and Waylands customers are supplied with a technical manual including exploded views and numbered parts, which means they can easily order and replace panels themselves, including all surface panels, corner posts, doors, and access hatches.

The distinctive curved edges, and careful use of colour soften the appearance of the large Calibur3 metal enclosure, giving it a sleek, modern appearance. The quality and workmanship complements the cutting-edge technology it protects, allowing it to fit seamlessly into a high-spec advanced manufacturing environment.

The final product is manufactured and supplied to Wayland via one of our prefered partners in South Wales just a few miles down the M4, locally positioned to Papa Bravo.

With extensive hands on knowledge on sheet metalwork and manufacturing process at Papa Bravo working with such a local a premium partner with production manufacturing capabilities enables an almost seamless transition to higher volumes.