Henrob

Poke Yoke Frangible Packaging

The Henrob Poke Yoke rivet packaging system enables fully automated error proof rivet supply.

Specialist packaging design was the brief when Papa Bravo were approached by Atlas Copco to develop a poke yoke system for holding and transporting stainless steel rivets, which are used in the fabrication of car body panels.

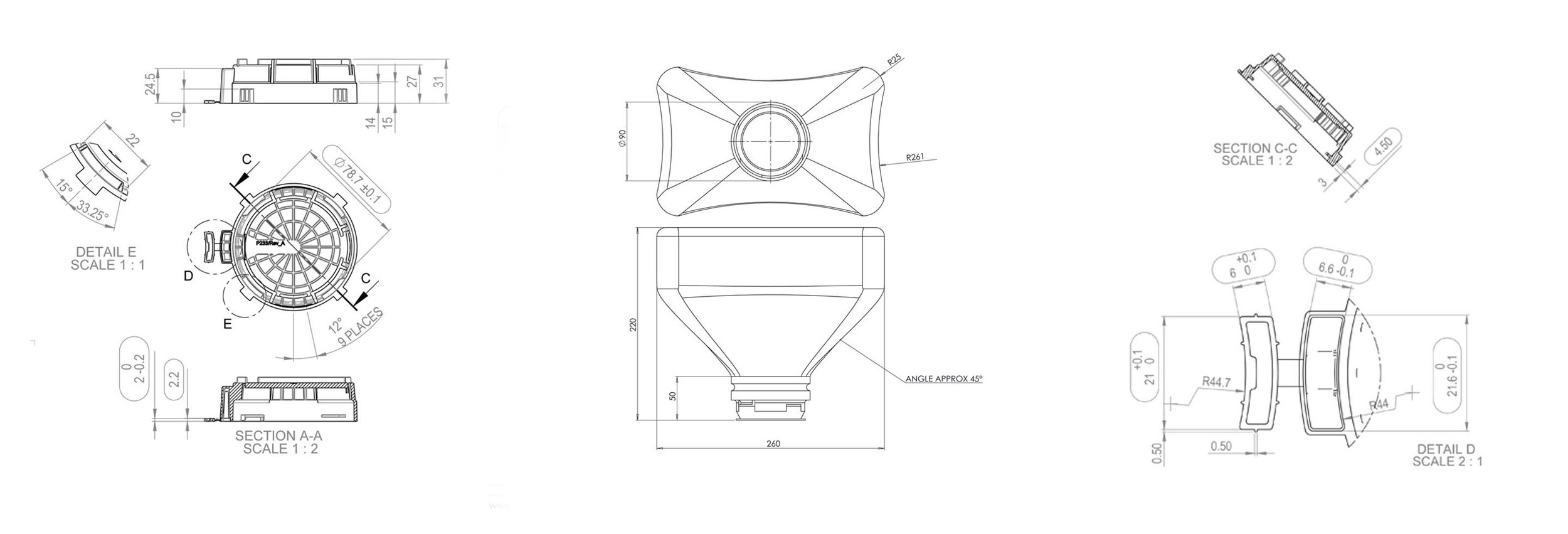

The key technical challenges that needed to be overcome during this project included: generating a bottle and cap solution that was robust enough to house a large quantity of rivets; designing the cap to incorporate a frangible seal that allowed the rivets to be dispensed; and developing a poke yoke feature that would prevent the rivet bottle from being loaded into an incorrect riveting system.

The final solution for the Packaging Design was presented to the senior technical team as a injection-moulded polypropylene cap with poke yoke positioning bosses and a quick-release living hinge, enabling the bottle contents to be emptied.

Both the cap and blow-moulded high-density polyethylene bottle were also developed to withstand heavy handling and absorb shock and impact when dropped from a one metre height.

Consistent client liaison throughout this design and development project meant that the end result encapsulated all of the original product requirements. Due to the high level of client confidence in the final design, they were keen to progress rapidly to product tooling, manufacture, and supply of the fully finished parts.